Spray Coating and Development Services

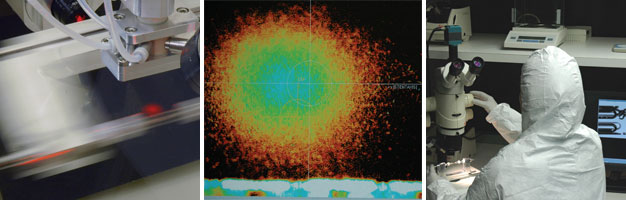

ioos offers a coating service for combination devices and for other high demanding applications which provides a competitive advantage to our customers. The coating process can be easily adapted for specific devices, materials, and active substances. It is controlled using innovative Process Analytical Technology. Device coating is performed in a Class 10.000 cleanroom. Coating weight is measured with micro balances and surface properties are controlled using, among others, high-resolution optical microscopy and scanning electron microscopy (SEM).

Click on nd-film for more information on smooth and homogeneous coatings

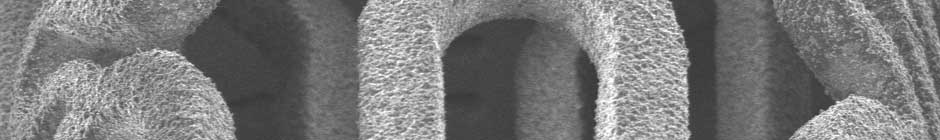

Using ioos' "scaffold-on-device" approach textured coatings and membranes, which may contain active substances, can be easily produced and reproducibly applied on a particular device. For more information on coatings having a determined nano-micro structure and surface features see texsel and tutela.

Quality problems in various spray nozzles are detected and the coating processes is controlled using ioos' SEP Spray Error Patternation systems. The systems feature a novel quality procedure and metrics for spray pattern analysis and spray process monitoring and control. SEPPAT for in-situ process control allow for reproducible system setup and calibration and provides enhanced process control by continuously monitoring and controlling the performance of the spraying device. Please visit the website www.spraydiagnostic.com for more information on spray process control.